Unveiling the Secrets Behind Solar Power: Discover the Future of Clean Energy Manufacturing!

As the world grapples with the impact of climate change and the urgent need for sustainable energy solutions, solar power manufacturing has emerged as a cornerstone of the clean energy revolution. This industry is not only pivotal in reducing our carbon footprint but also in providing energy independence and security. The increasing demand for renewable energy sources has propelled solar power into the spotlight, making it essential to understand the intricate processes, innovative technologies, and advancements that are shaping this field. In the following sections, we will explore the various aspects of solar power manufacturing, from the materials used to the cutting-edge technologies that drive efficiency and performance. Join us on this enlightening journey into the world of solar energy as we uncover the secrets behind its manufacturing and its vital role in our sustainable future.

Understanding Solar Power Manufacturing

Solar power manufacturing encompasses the entire process of producing solar panels, which convert sunlight into electricity. This process is critical in the energy sector, as it directly impacts the efficiency and affordability of solar energy systems. The solar industry has witnessed significant growth over the past decade, driven by technological advancements and increasing awareness about climate change. It involves a series of complex steps that transform raw materials into functioning solar panels ready for installation in residential and commercial settings. Understanding the nuances of solar power manufacturing is essential for grasping how these systems can contribute to a sustainable energy future. As more individuals and businesses seek clean energy solutions, the importance of efficient manufacturing processes cannot be overstated, as they ensure high-quality products that meet the growing energy demands.

Key Processes in Solar Power Manufacturing

The manufacturing of solar panels is a multi-step process that begins with material selection and culminates in the assembly of solar modules. Each step is crucial to ensuring that the final product is efficient, durable, and capable of withstanding the elements. The first stage involves selecting the appropriate materials, which can significantly influence the performance of solar panels. Following this, the production of solar cells takes place, where advanced techniques are employed to create cells that can effectively convert sunlight into electricity. Finally, these cells are assembled into modules, where they are encapsulated and framed to protect them from environmental conditions. Each of these processes is vital in determining the efficiency and longevity of solar panels, making it essential for manufacturers to employ the best practices in the industry.

Material Selection

Material selection is the cornerstone of solar power manufacturing. The most commonly used material in solar panels is silicon, which has proven to be an effective and efficient conductor of electricity. Silicon is favored due to its abundance and the technological familiarity that manufacturers have with it. However, the rise of alternative materials, such as cadmium telluride and copper indium gallium selenide, is also gaining traction, especially in thin-film technologies. Each material has its own impact on the efficiency and performance of solar panels, which directly affects energy output and cost. For instance, while silicon-based panels are known for their reliability and efficiency, innovative materials could offer lighter, more flexible options for diverse applications.

Cell Production

The production of solar cells involves several intricate processes, including doping, etching, and the application of photovoltaic technology. Doping is a crucial step in which impurities are added to silicon to enhance its conductivity. This process creates a p-n junction, which is essential for generating an electric field within the solar cell. Following doping, the cells undergo etching to create a textured surface that minimizes reflection and maximizes light absorption. The final step involves the application of photovoltaic technology, wherein the cells are treated to ensure optimal performance under sunlight. Innovations in this phase have led to the development of higher efficiency cells, which can convert more sunlight into usable electricity.

Module Assembly

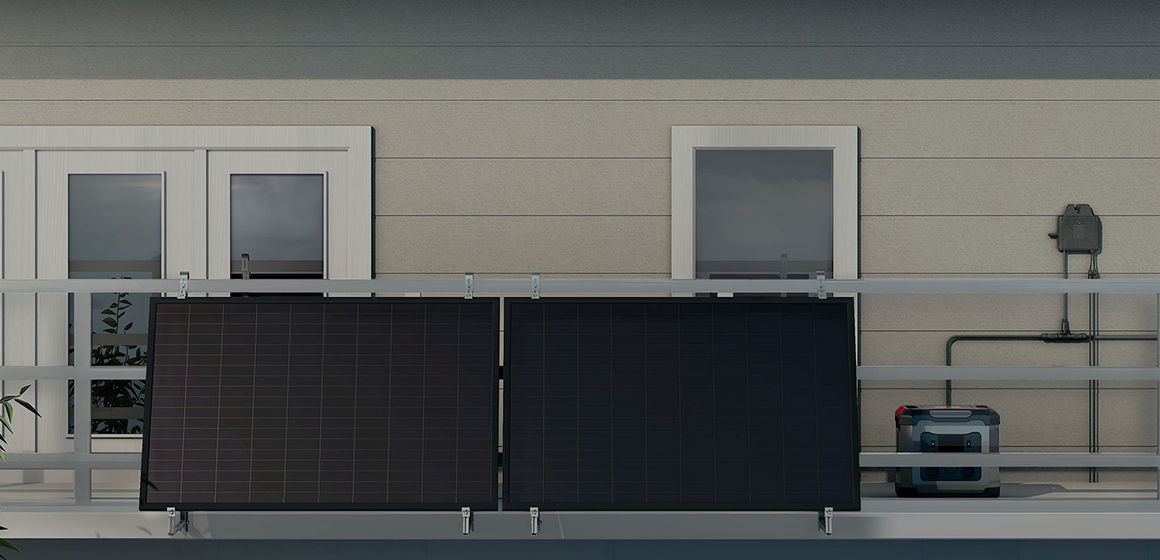

After the solar cells are produced, the next phase is module assembly. This involves encapsulating the solar cells between layers of protective material to shield them from environmental factors. The encapsulation process is critical, as it prevents moisture and dirt from degrading the cells' performance over time. Once encapsulated, the cells are framed using aluminum or other durable materials, providing structural integrity. This assembly process is not only about protection but also about ensuring that the panels can be easily installed and maintained. Manufacturers continuously seek ways to improve assembly techniques to enhance efficiency and reduce production costs, ultimately making solar energy more accessible to consumers.

Innovations in Solar Power Technology

The field of solar power manufacturing is constantly evolving, with exciting innovations emerging regularly. One such advancement is the development of bifacial solar panels, which capture sunlight on both sides, significantly increasing energy output. Thin-film solar cells are another breakthrough, offering lightweight and flexible options that can be integrated into various surfaces, from building materials to clothing. Additionally, energy storage solutions, such as advanced lithium-ion batteries, are being designed to work seamlessly with solar energy systems, allowing for the storage of excess energy generated during the day for use at night or during cloudy periods. These innovations are not only enhancing the efficiency of solar power systems but also expanding their applications, making solar energy a more viable option for a broader range of consumers.

The Future of Solar Power Manufacturing

As we look to the future of solar power manufacturing, several trends and developments are on the horizon. Automation is expected to play a significant role in streamlining production processes, reducing costs, and increasing output. The integration of artificial intelligence and machine learning into manufacturing systems will enhance quality control and operational efficiency. Furthermore, sustainability practices are becoming increasingly important, with manufacturers seeking ways to minimize waste and utilize recycled materials in production. As the market for solar energy continues to expand, driven by both consumer demand and government incentives, the potential for growth in solar power manufacturing is immense. This sector is poised to play a critical role in the transition to a cleaner, more sustainable energy landscape.

Summarizing the Importance of Solar Power Manufacturing

In conclusion, solar power manufacturing is a dynamic and essential component of the clean energy landscape. From the careful selection of materials to the intricate processes involved in cell production and module assembly, each aspect of manufacturing plays a significant role in determining the efficiency and viability of solar energy systems. As innovations continue to reshape this industry, the future looks promising, with advancements in technology paving the way for greater accessibility and efficiency. Embracing these developments will not only aid in achieving clean energy goals but also contribute to a more sustainable future for our planet. Understanding the nuances of solar power manufacturing is crucial for anyone interested in participating in this exciting and transformative field.