Unlock Your Creativity: Discover the Magic of ABS Filament for Stunning 3D Prints!

3D printing has revolutionized the way we create, enabling enthusiasts and professionals alike to bring their ideas to life with unparalleled precision. One of the most critical components of this process is the choice of filament, the material that forms the final product. Among the various types available, ABS filament stands out for its remarkable properties and versatility. Known for its durability and strength, ABS (Acrylonitrile Butadiene Styrene) filament is widely used in many applications, ranging from simple prototypes to intricate artistic designs. In this article, we will explore how ABS filament can enhance your creativity in 3D printing projects, unlocking a world of possibilities for makers and innovators.

What is ABS Filament?

ABS filament is a thermoplastic polymer that is widely used in 3D printing due to its desirable physical properties. Composed of three main components—acrylonitrile, butadiene, and styrene—this filament exhibits a unique combination of strength, flexibility, and heat resistance. These attributes make ABS an excellent choice for creating durable parts that can withstand impact and higher temperatures, which is particularly important for functional prototypes and mechanical components. Additionally, ABS filament is relatively lightweight, making it easy to work with and transport. My friend John, who runs a small 3D printing business, swears by ABS for most of his projects, citing its reliability and the quality of the finished prints. He often recommends it to newcomers looking for a sturdy material that can handle the demands of various applications.

Benefits of Using ABS Filament for 3D Printing

One of the primary benefits of using ABS filament is the exceptional finish quality it offers. Prints made with ABS have a smooth surface and can be easily sanded or painted, making them ideal for artistic projects and professional prototypes. Furthermore, ABS is known for its ease of post-processing; it can be easily glued, machined, or even vapor smoothed to achieve a glossy finish. This versatility allows creators to experiment with intricate designs and achieve the desired aesthetic. Additionally, ABS filament is suitable for a wide range of applications, from toys and household items to automotive parts and even custom tools. My friend Sarah, an artist, recently created a series of stunning sculptures using ABS, demonstrating the material's potential for artistic expression. The durability and reliability of ABS filament mean that her creations can withstand the test of time, both in aesthetics and functionality.

Factors to Consider When Purchasing ABS Filament

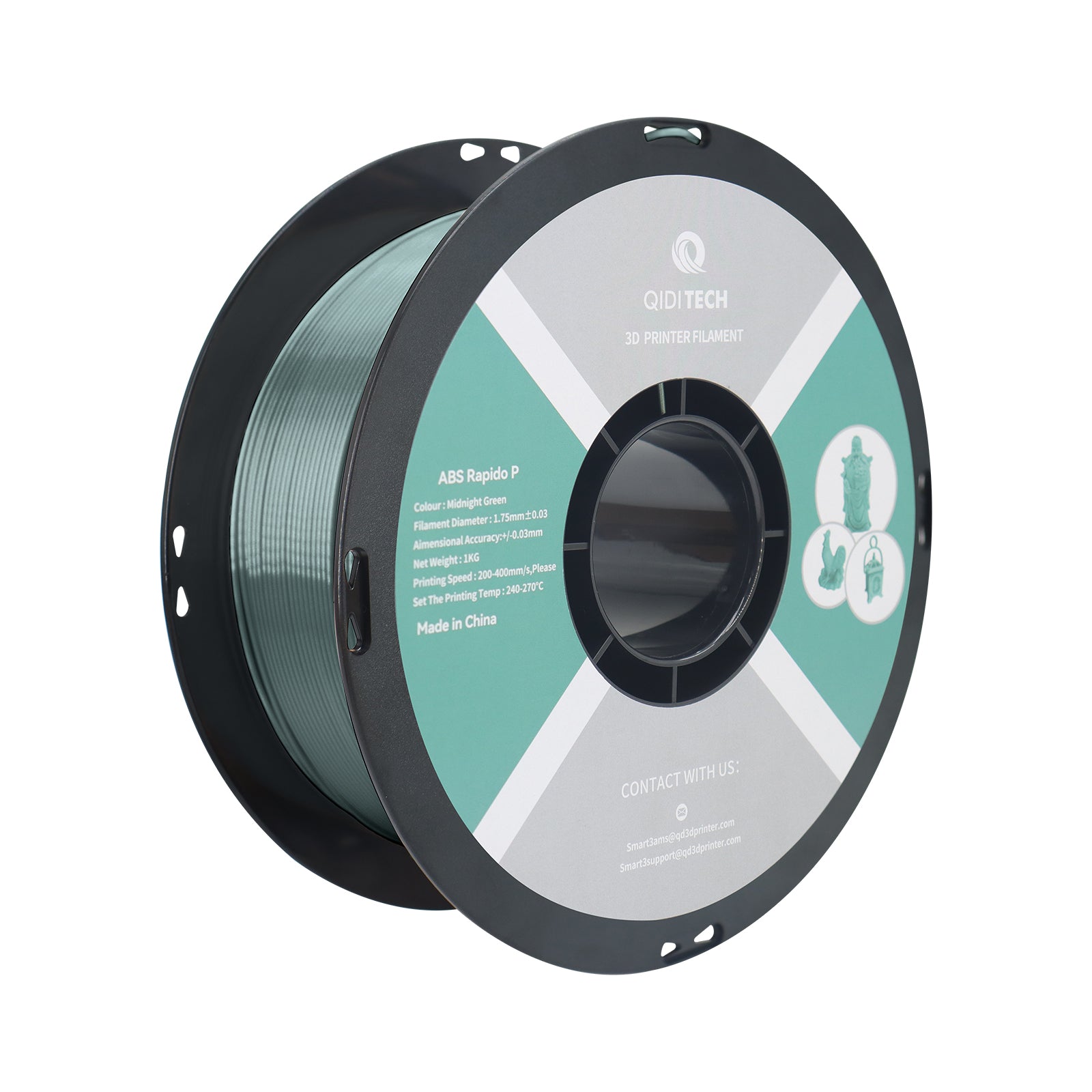

When it comes to purchasing ABS filament, several crucial factors should be considered to ensure a successful printing experience. Filament diameter is one of the first things to check, as different 3D printers require specific sizes, typically 1.75mm or 2.85mm. Additionally, color options vary widely, allowing you to select hues that match your project’s aesthetic. Another important aspect is quality; look for ABS filament that is known for consistent diameter and minimal impurities, as this will lead to smoother prints and fewer clogs. Compatibility with your specific 3D printer model is also vital; not all printers are optimized for ABS, so checking the manufacturer’s guidelines can save you from potential headaches. Lastly, sourcing your filament from reliable suppliers is essential. This ensures you receive a quality product that performs well. A misstep in any of these factors could lead to frustrating printing experiences that might discourage budding creators.

Tips for Successful 3D Printing with ABS Filament

To achieve the best results when printing with ABS filament, there are several practical tips to keep in mind. Firstly, optimal temperature settings are crucial; most ABS filament prints well at a nozzle temperature of around 220-250°C and a heated bed temperature of 80-110°C. Proper bed adhesion is another key factor; using a heated bed or applying a glue stick or specialized adhesive can help prevent warping, which is common with ABS. Ventilation is also critical—printing with ABS can release fumes that are harmful if inhaled over prolonged periods. Ensure your workspace is well-ventilated or consider using an enclosure with a filtration system. Finally, troubleshooting is part of the learning curve; if you encounter issues like warping or stringing, adjusting the settings or refining your printing techniques can lead to improvements. My friend Mike, who has faced numerous challenges while printing with ABS, often emphasizes the importance of patience and experimentation, which ultimately leads to better prints and enhanced skills.

Unlocking the Full Potential of ABS Filament

In summary, ABS filament is a powerful tool for anyone looking to explore the creative potential of 3D printing. Its strength, flexibility, and ease of post-processing make it an ideal choice for a wide variety of projects, from prototypes to artistic endeavors. By understanding its properties, the benefits it offers, and the key factors to consider when purchasing, you can unlock new levels of creativity in your 3D printing journey. I encourage you to experiment with ABS filament in your next project—whether you're a seasoned maker or just starting out—embracing the magic of this versatile material can lead to truly stunning results.