Unlock the Secrets of 3D Printing: Discover the Ultimate Slicer Software for Your Creative Projects!

3D printing has revolutionized the way we approach creativity, allowing individuals and businesses to turn digital concepts into tangible realities. From intricate designs to practical prototypes, the possibilities are virtually endless. However, to bring these ideas to life, one crucial component is required: slicer software. This specialized tool serves as the bridge between 3D models and the printers that fabricate them, converting complex designs into a language that printers can understand — G-code. In this article, we'll explore various slicer options available to users, helping you find the perfect fit for your creative endeavors.

Understanding 3D Printing Slicers

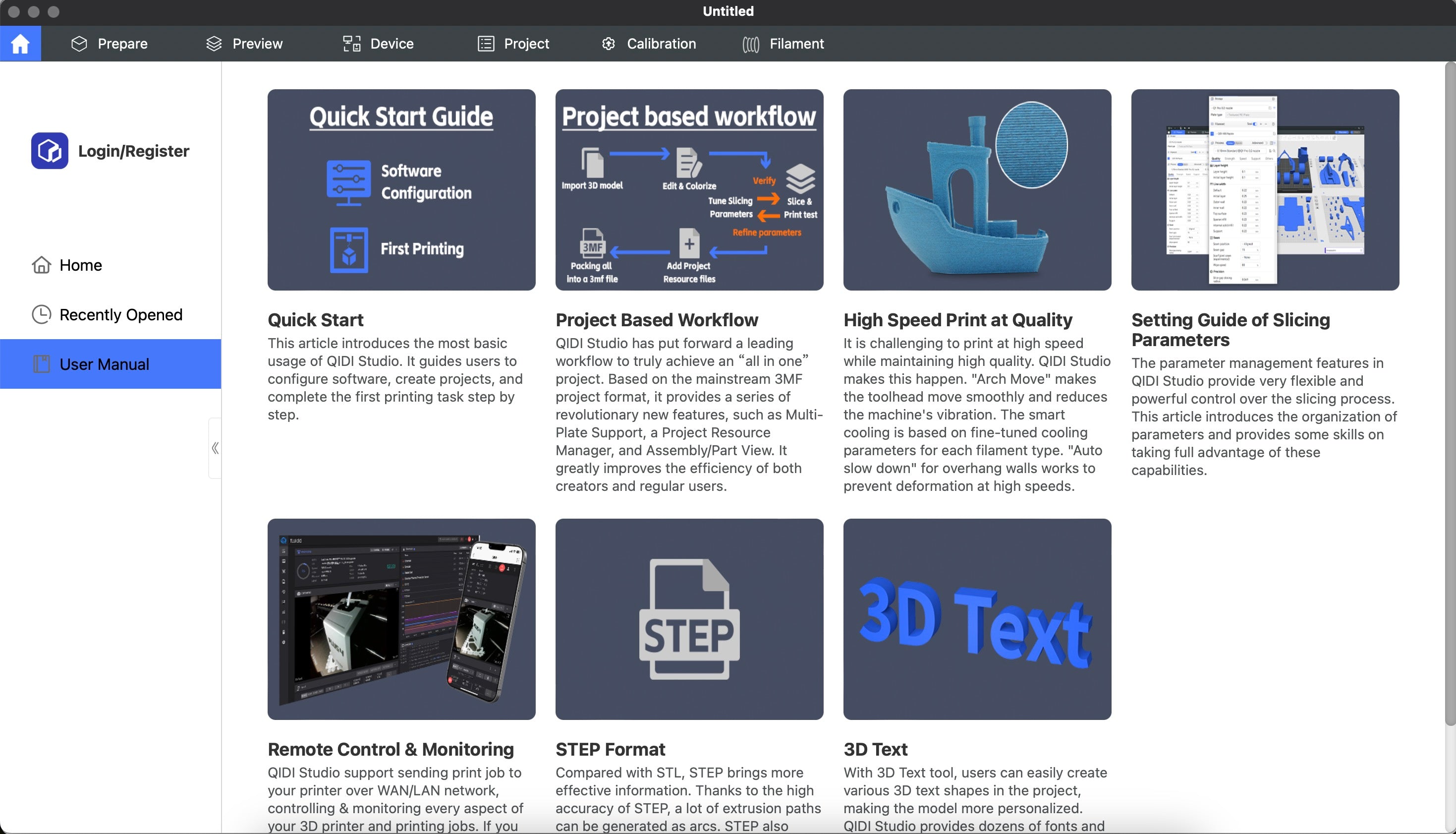

Slicer software plays a pivotal role in the 3D printing workflow. At its core, a slicer is a program that takes a 3D model, often created in CAD software, and converts it into G-code, which is the set of instructions that tells a 3D printer how to execute the print job. The slicer analyzes the model's geometry, determines optimal layer heights, infill patterns, and support structures, and ultimately generates the path that the printer’s nozzle will follow. This conversion is essential because it not only defines how the object will be built layer by layer, but also impacts print quality, speed, and material efficiency. Understanding this process is critical for anyone looking to achieve successful prints and maximize their 3D printing experience.

Key Features of Slicer Software

When selecting a slicer software, several key features should be considered to ensure it meets your specific needs. Firstly, the user interface is paramount; a clean, intuitive design can streamline your workflow, making it easier to navigate complex settings. Customization options are equally essential, allowing users to tweak print settings such as temperature, speed, and infill density to suit different materials and project requirements. Additionally, compatibility with various printer types is crucial; not all slicers work with every printer, so checking this compatibility beforehand can save a lot of frustration. Lastly, slicing speed can significantly affect your overall productivity, especially for extensive printing projects. Finding software that balances quality and speed is key to efficient 3D printing.

Popular Types of Slicer Software

Slicer software can be broadly categorized into open-source and proprietary options, each with its own set of advantages and disadvantages. Open-source slicers are typically free and benefit from community-driven support and development, meaning users can often find solutions to problems quickly or even modify the software to better suit their needs. However, they may lack some advanced features or user support that proprietary slicers offer. On the other hand, proprietary slicers often come with polished interfaces and customer support, but they may require a purchase or subscription fee. Understanding these differences can help you make an informed decision that aligns with your budget and technical requirements.

Choosing the Right Slicer for Your Projects

Choosing the right slicer software for your 3D printing projects involves evaluating various aspects based on your specific needs. Consider the type of material you plan to use, as some slicers are better suited for certain materials than others. For instance, if you’re working with flexible filaments, ensure your slicer has settings to accommodate them. Additionally, think about the complexity of your prints; intricate designs may require advanced features, such as supports and adaptive layer heights, which not all slicers provide. Personal preferences also play a role; whether you prefer a simple interface or an abundance of customization options can guide your choice. Testing out different slicers on smaller projects can help determine which one resonates best with your workflow.

Future Trends in Slicer Technology

The world of slicer software is continually evolving, with exciting trends on the horizon. One notable development is the integration of artificial intelligence (AI) into slicer technology, which has the potential to optimize print settings automatically based on user preferences and model complexity. Additionally, cloud-based solutions are gaining traction, allowing users to access their slicers from anywhere and collaborate on projects in real-time. Community-driven developments are also becoming more prevalent, with users contributing to software enhancements and features that benefit the wider 3D printing community. Keeping an eye on these trends can help you stay ahead in your 3D printing journey.

Selecting the Ideal Slicer Software for Success

In conclusion, selecting the right slicer software is paramount for achieving successful 3D printing results. The choice can significantly affect the quality, efficiency, and complexity of your projects. By exploring different options and experimenting with various features, you can enhance your creative endeavors and bring your ideas to life more effectively. Don't hesitate to dive into the world of slicers and discover which software aligns best with your 3D printing goals.