Unlock Your Creativity: Discover the Secrets of Buying the Perfect ABS Filament for Stunning 3D Prints!

In the world of 3D printing, the choice of filament can significantly impact the outcome of your projects. Among the various materials available, ABS filament stands out as a favorite among makers, hobbyists, and professionals alike. Its unique combination of durability, ease of printing, and post-processing potential makes it an ideal choice for creating functional and artistic pieces. This article aims to guide you through the process of selecting the right ABS filament for your 3D printing endeavors. By understanding its benefits, characteristics, and the factors that influence your purchase, you can elevate your printing projects and unlock your creative potential.

Understanding ABS Filament

ABS filament, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer that is widely used in 3D printing. Its chemical composition consists of three monomers: acrylonitrile, butadiene, and styrene, which together create a material known for its strength and resilience. One of the primary advantages of ABS is its excellent durability, making it suitable for creating parts that require impact resistance. Additionally, ABS prints typically have a smooth surface finish, which is perfect for applications where aesthetics matter. However, it's important to be aware of some challenges associated with ABS filament. It is known to warp during the cooling process and can emit fumes that may be harmful in poorly ventilated spaces. Adequate ventilation and proper print settings can help mitigate these issues, ensuring a successful printing experience.

Factors to Consider When Buying ABS Filament

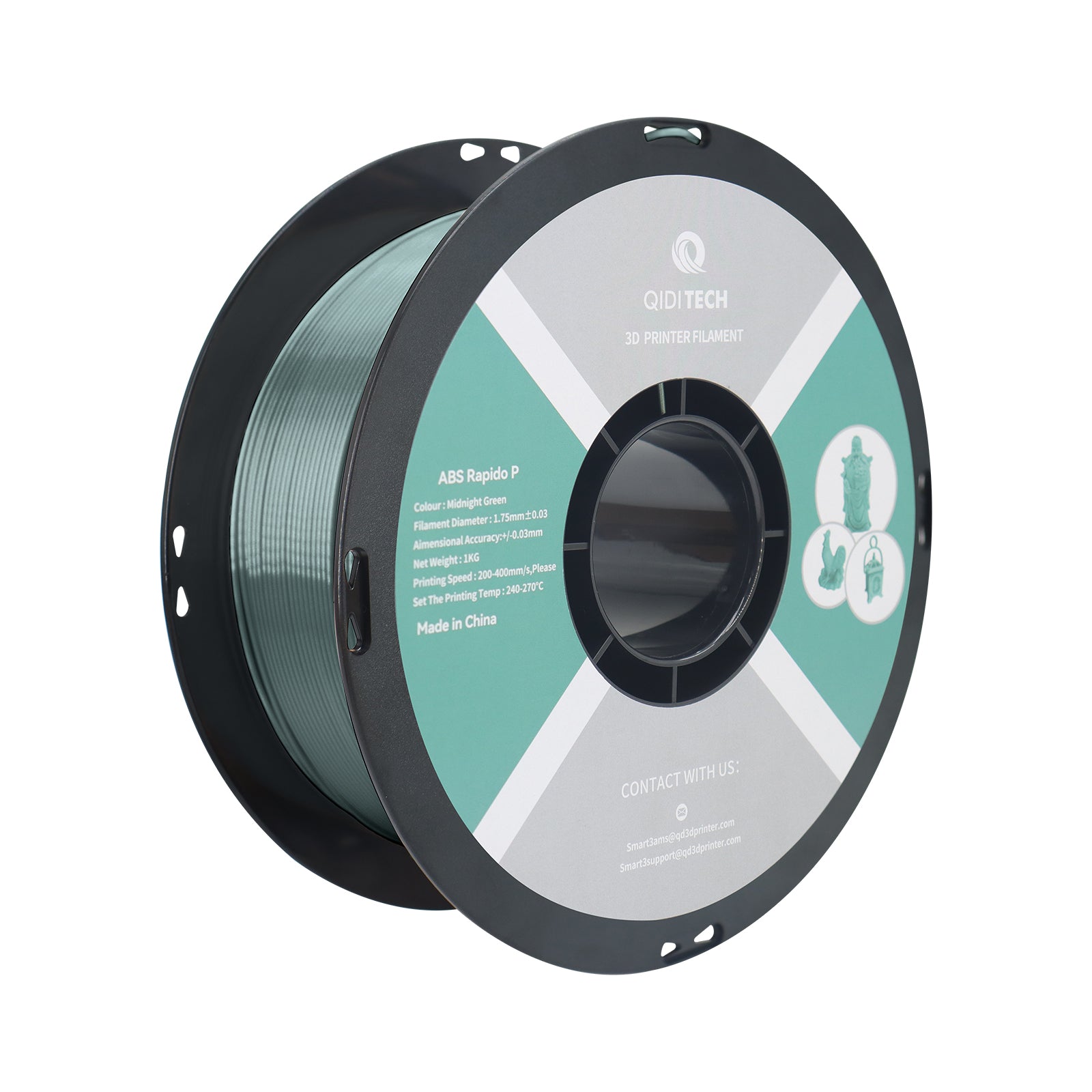

When purchasing ABS filament, several key factors should be taken into account to ensure you choose the right product for your needs. First, consider the diameter of the filament, which typically comes in 1.75mm and 2.85mm sizes. The diameter must match your 3D printer's specifications to avoid feeding issues. Next, explore the color options available. ABS filament comes in a wide range of colors, allowing you to customize your prints according to your preferences. Additionally, check the spool weight, as larger spools can provide more filament at a better value, but make sure your printer can accommodate the weight. Compatibility is also crucial; ensure that the ABS filament you choose is suitable for your specific printer model. Lastly, the quality of the filament is paramount. Sourcing from reputable suppliers can help you avoid low-quality materials that can lead to printing failures and frustration.

Understanding Filament Specifications

Filament specifications play a crucial role in the printing process. For ABS, the recommended nozzle temperature is typically between 210°C and 250°C, while the heated bed should be set to around 80°C to 110°C. These temperatures help to reduce warping and improve adhesion. Print speed is another important factor; slower speeds can enhance print quality, especially with intricate designs. Understanding these specifications and adjusting your printer settings accordingly can greatly impact the quality of your ABS prints, leading to successful and visually appealing results.

Where to Buy ABS Filament

Finding the right ABS filament can be done through various avenues. Online marketplaces offer a vast selection of filaments from different manufacturers, making it easy to compare prices and options. However, the downside may include the inability to physically inspect the filament before purchase. Specialty stores often carry high-quality filaments and provide knowledgeable staff to assist you in making the right choice. Local suppliers may also offer the advantage of immediate access to the product, allowing you to start your project right away. Each option presents benefits and drawbacks, so consider what works best for your situation and preferences.

Tips for Working with ABS Filament

To achieve the best results when printing with ABS filament, consider implementing several practical tips. First, ensure your printer settings are optimized for ABS, including the correct temperature settings and print speed. Preparing the print bed with a suitable adhesive, such as glue sticks or specialized adhesives, can significantly improve adhesion and reduce warping. Additionally, printing in a well-ventilated area or using an enclosure can help manage fumes and maintain a stable temperature environment, enhancing print quality. Finally, exploring post-processing techniques like sanding or acetone vapor smoothing can elevate your finished product, giving it a professional look.

Optimal Selection for 3D Printing Success

In summary, selecting the right ABS filament is crucial for achieving outstanding 3D prints. Understanding its properties, considering key purchasing factors, and applying effective printing tips can significantly enhance your projects. As you embark on your 3D printing journey, don't hesitate to experiment with different filaments and settings to find what works best for you. With the right ABS filament in hand, you're well on your way to unlocking your creativity and bringing your imaginative designs to life.